Over 90 Years of Experience in the Textile Industry

In 1931, Carla Soren Thygesen began a journey that would link the name Thygesen Textile Group (Denmark) with quality in designing, manufacturing and selling textile products.

Thygesen Textile Vietnam – Ethical Apparel Manufacturing Partner is proud to be part of this incredible journey. Learned from a century of experience and expertise, we are now one of the leading clothing manufacturers in Vietnam, delivering our goods to the world market.

Mission

To inspire and motivate change toward True Values and Sustainable Development.

Vision

To become a prestigious textile supplier in Vietnam and worldwide while continually bringing True Added Values to our customers, partners, employees, and shareholders.

Core Values

From the beginning, Thygesen Textile Vietnam has strived to translate our core values into everything we do. Truthfulness, Compassion, Kindness, Commitment, and Persistence are what made us a prestigious and sustainable textile manufacturing company today.

Product Lines

We specialize in manufacturing activewear, casualwear, kidswear, underwear, etc. offering high-quality apparel to best suit your demands.

Every garment is made with care, in our own SA8000 and WRAP certified sewing factory.

Our Capabilities

With over 90 years of experience in textile industry, we support many global fashion brands as a trusted clothing manufacturer, bringing their designs to life through full-package OEM/ODM solutions, innovative product development consulting, sustainable and efficient manufacturing.

Continuous Efforts for R&D

LEAN Manufacturing System

OEM/ODM Manufacturing

Certified Fabrics

800k

pcs/month

16

steps process

90+

Years of experience

2

more factories in 2026

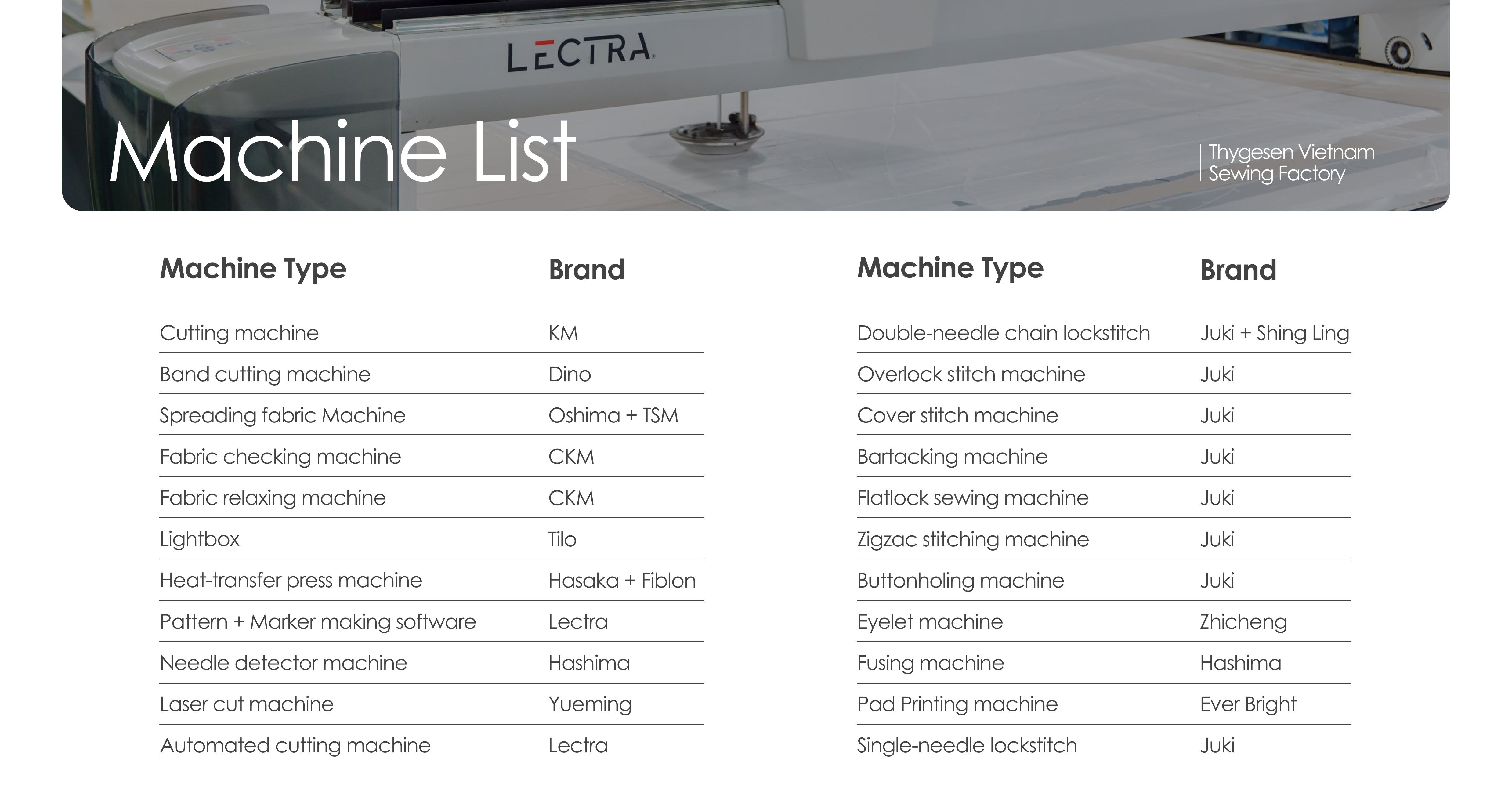

Our Advanced Machine List

Our factory is equipped with advanced machinery and modern technology, enabling efficient operations and maintaining high-quality, consistent products for bulk production.

Our Process Setup is Optimized for Mass Production

Step 1

Handle Customer’s Inquiry

Send us an inquiry and share more details about your projects, and our dedicated team will handle it.

Step 2

Make Quotation

If your project is suitable for our standard MOQ and production, then we offer an initial quotation based on the techpack, selected fabric quality, and quantity.

Step 3

Sample Development

After the customer’s approval of the quotation, we proceed with sample development to confirm quality before starting bulk production.

Step 4

Bulk Production

Following order confirmation and a deposit, we initiate bulk production with all specifications carefully followed.

Step 5

Quality Control

We follow strictly our QC procedures, ensuring 100% end-line inspections. We also apply AQL 2.5 for final inspections. Third-party QC is always welcome.

Step 6

Packaging & Shipping

Once the quality is confirmed, the finished products are carefully packaged and shipped in bulk to your warehouse.

Thygesen Working Process

From Inquiry to Finished Garments

As one of trusted OEM Vietnam apparel manufacturers, Thygesen is proud to serve well-known brands including Tommy Hilfiger, DKNY, Calvin Klein, Fjällräven, Girlfriend Collective, Ninepine, and Boody. We offer a full-service solution, delivering high-quality products and reliable expertise to markets across the US, UK, EU, Australia, and Japan.

Discover how we take you through every step of the process, from the first point of contact to the final packaged products.

Our Clients Say

FAQs

1. What distinguishes Thygesen as one of the best apparel manufacturers?

- We are proud to be one of a few clothing Vietnam clothing manufacturers specializing in full-package production handling from design consultation, to material sourcing, bulk production and shipping.

- All products are manufactured in our SA8000 and WRAP-certified factory with premium quality, meeting prestigious international certifications such as ISO 9001:2015, GRS, GOTS, OEKO-TEX STANDARD 100, OEKO-TEX STeP, FSC, and OCS.

- Our commitment to ethical manufacturing, honest partnerships, and transparency at every stage

2. What is Thygesen's minimum order quantity (MOQ)?

As a mass-scaled apparel manufacturer, our standard MOQ is 3,000 pieces per design for casual or activewear items like T-shirts, hoodies, leggings, bras…, with different colors and sizes. For underwear, the MOQ is between 5,000 to 10,000 pieces per style. Please note that the MOQ may be higher for certain materials and styles.

3. Is Thygesen a sustainable clothing manufacturer?

Yes, we are committed to ethical and sustainable practices, creating positive impacts for the environment, people, and society. In addition, as a trusted sustainable clothing manufacturer, we focus on waste reduction, eco-friendly materials, and LEAN processes while prioritizing our team’s well-being.

4. As a sustainable clothing manufacturer, what fabrics does Thygesen use?

We can source/develop sustainable fabrics based on your needs, including organic cotton, bamboo, TENCEL™, ECOVERO™, hemp, recycled polyester, recycled nylon, etc.

5. Does Thygesen provide samples?

We certainly do. The number of sampling rounds can vary depending on complexity; however, with our experience as a clothing manufacturer, we usually require only 2–3 rounds to finalize samples. Using available fabrics, sampling typically takes 7–10 days. The sampling fee is charged in advance and will be refunded once the bulk order is confirmed.

6. What is the average lead time for bulk production?

Normally, operating as a full-service apparel manufacturer, our standard bulk production lead time is 30–45 days after all fabrics and trims have arrived.

7. What is Thygesen's production capacity?

We produce up to 800,000 garments per month, totaling nearly 10 million pieces annually, across a wide range of categories including Activewear, Underwear, Casualwear, Kidswear, Workwear, and Uniforms.

8. Which fashion brands are Thygesen’s customers?

With decades of expertise in the textile industry, we serve top global brands including Tommy Hilfiger, DKNY, Calvin Klein, Fjällräven, Girlfriend Collective, Ninepine, and Boody.

9. What customization services do you offer?

With integrated sourcing and production capabilities as an apparel manufacturer, we provide extensive customization options including fabric and accessories, custom prints, embroidery, hangtags, labels, and packaging – to meet our clients’ unique needs.

10. How to find the right clothing manufacturer?

- Define your product requirements: Clearly specify your product details such as: styles, estimated order quantity, fabric preferences , quality expectations.

- Check capabilities and services: Ensure the manufacturer can handle your required volume and meet your launch deadlines and evaluate their experience, production output, and ability to maintain quality standards at scale.

- Request product samples: Evaluate sample quality before bulk production. Fees are often refunded with an order.

- Assess quality control: Ask about QC processes across all stages to see if they apply AQL standards, 100% inspection, or use third-party audits.

- Check logistics and shipping options: Clarify if they offer FOB, DDP, or other terms, and who manages customs and delivery.

- Visit the factory if possible: A factory tour helps verify production process, labor quality, facilities, and working environment.

- Evaluate communication: Choose a clothing manufacturer who is responsive, transparent, and communicates clearly in your preferred language.

Start Your Production with Thygesen Vietnam

News

From the latest trends in textile manufacturing to our newest activities and achievements, stay connected with the industry through the lens of an apparel manufacturer and keep your finger on the pulse with our news.