Crossback Sports Bra offers both style and support, making it a go-to choice for activewear. Thygesen provides full-package services, handling everything from fabric sourcing to packaging for a seamless production process.

Thygesen Vietnam

Your Trusted Partner in Premium Sports Bra Manufacturing

Understanding Functional Needs: Custom Leggings for Specific Purpose

Why Choose Thygesen As Your Sports Bra Manufacturing Partner?

We Source High Quality Fabric

From Trusted Suppliers

Customized to Perfection -

Bring Your Ideas To Life

Crafted by Skilled Labor,

Powered by Technology

Commitment to Sustainability & Ethics

In Every Stich

Dedicated & Experienced Team

You Can Rely On

We Bring All Your Sports Bra To Life with Passion and Care

How Are Our OEM/ODM Solutions Different?

| Thygesen (FOB) | Traditional Clothing Manufacturer (CM) | |

|---|---|---|

| Full Package Service (From fabric sourcing to production and shipping) | ||

| Technical Design Assistance | ||

| Custom Labels, Hang Tags, Packaging | ||

| Cost Effective For Large Orders | ||

| Quality Assurance | ||

| Compliance & Global Certifications | ||

| Wide Network of Trusted Suppliers Both Local and Global | ||

| English Proficiency |

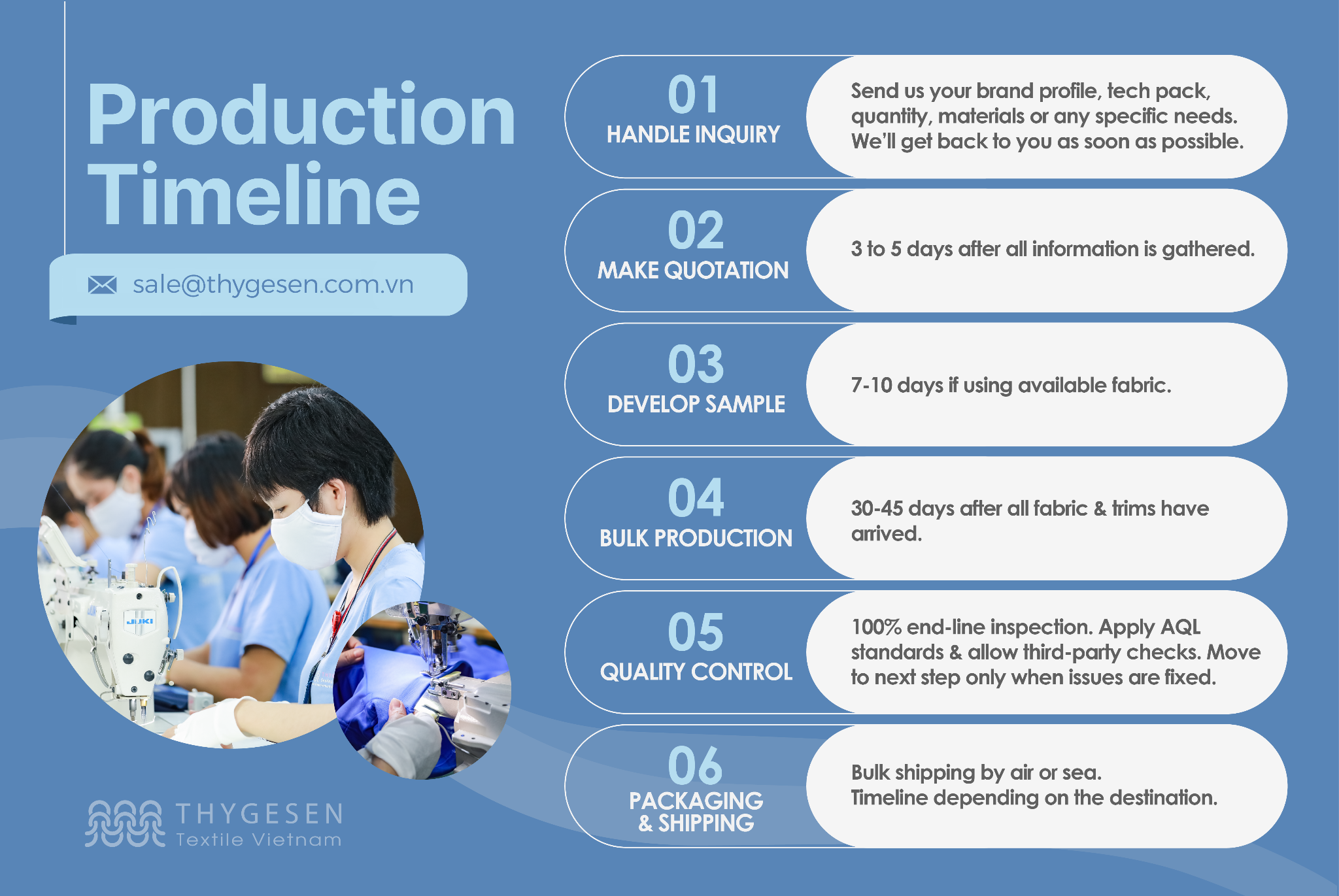

Our Process Setup is Optimized for Mass Production

Step 1

Handle Customer’s Inquiry

Send us an inquiry and share more details about your projects, and our dedicated team will handle it.

Step 2

Make Quotation

If your project is suitable for our standard MOQ and production, then we offer an initial quotation based on the techpack, selected fabric quality, and quantity.

Step 3

Sample Development

After the customer’s approval of the quotation, we proceed with sample development to confirm quality before starting bulk production.

Step 4

Bulk Production

Following order confirmation and a deposit, we initiate bulk production with all specifications carefully followed.

Step 5

Quality Control

We follow strictly our QC procedures, ensuring 100% end-line inspections. We also apply AQL 2.5 for final inspections. Third-party QC is always welcome.

Step 6

Packaging & Shipping

Once the quality is confirmed, the finished products are carefully packaged and shipped in bulk to your warehouse.

Sports Bra Manufacturers: Buyer's Guide for All Fashion Brands

Partnering with the right sports bra manufacturer or a versatile athletic clothing manufacturer can determine your product’s success. In this guide, we break down sports bra types, material choices, and quality insights that every brand should know before starting production.

1. Different Types of Sports Bra By Support Level

Choosing the right support level is crucial to ensure comfort, performance, and functionality for different types of activities.

- Low Support: Designed for light-impact activities such as yoga, stretching, Pilates, or casual wear. These bras often feature softer fabrics, minimal compression, and lighter construction for all-day comfort.

- Medium Support: Suitable for moderate activities like cycling, power walking, or gym training. They balance comfort and stability with structured panels or wider straps to reduce bounce without restricting movement.

- High Support: Built for intense workouts such as running, HIIT, and aerobics. These styles offer maximum compression, reinforced underbands, and strong strap systems to keep everything securely in place during high-impact motion.

2. Common Fabric Composition for Sports Bras

Below are some common fabric blends used in sports bra manufacturing, typically combining a base fiber (like nylon, polyester, or cotton) with an elastic fiber (like spandex) to ensure stretch, comfort, and support. In most cases, the elastic component ranges from 10% to 20%, providing enough stretch for mobility without compromising shape retention or durability.

- Nylon/Spandex: Smooth, durable, and moisture-wicking – ideal for high-performance sports bras.

- Polyester/Spandex: Quick-drying and shape-retaining, great for intense workouts.

- Cotton/Spandex: Soft and breathable, best for low-impact or everyday wear.

- Recycled Polyester/Spandex: Sustainable option offering the same performance with a lower environmental footprint.

- Bamboo/Spandex: Naturally breathable and antibacterial, providing superior comfort.

3. Sports Bra Quality Checklist: What Brands Need to Know

Here’s a quick checklist of key quality factors every brand should consider when receiving finished samples or inspecting completed production batches:

- Fabric quality: The material should feel soft and smooth on the skin, stretch comfortably, and recover well after movement. It needs to be breathable and moisture-wicking to keep the wearer dry, while remaining durable enough to resist pilling, fading, or tearing even after repeated washing and use.

- Sizing and fit: Measurements must be accurate and consistent across batches. A well-fitted sports bra should support the bust properly without pinching or gaping, ensuring full comfort and stability during physical activity. The support level must match the intended purpose (e.g., light, medium, or high impact).

- Stitching and seams: Seams should be even, reinforced at stress points, and lie flat against the skin to avoid chafing. Threads should be trimmed cleanly with no loose ends or skipped stitches that could indicate weak construction.

- Elasticity and support: Elastic underbands and shoulder straps should have strong stretch and recovery without rolling or losing shape. Straps must stay in place and maintain tension during movement, and the fabric should compress the bust comfortably without restricting breathing.

- Accessories and details: Cups and padding need to be well-shaped and secure, with even thickness and alignment. Fasteners like hooks, zippers, or clasps must function smoothly with no sharp edges. Labels and logos should be neatly attached or printed and resistant to washing or peeling.

- Color and appearance: Colors must be consistent across the entire batch, with no visible shade variation. Fabric should be smooth and even, free from stains, snags, or shine inconsistencies. The garment should pass colorfastness tests for washing, sweat, and friction.

- Performance and functionality: The bra should maintain support during movement, minimize bounce, and allow full mobility of the shoulders and chest. Breathable panels or mesh inserts should function effectively, and the overall construction should match the activity type (e.g., yoga, running, training).

- Packaging: Each product should be neatly folded, labeled correctly with size and care instructions, and packed in protective or eco-friendly materials. Packaging must safeguard the product from deformation, dust, or moisture, and be ready for retail display or shipment.

4. What an Experienced Sports Bra Manufacturer Can Bring to Your Brand

Partnering with an experienced sports bra manufacturer can provide significant advantages, helping brands deliver high-quality, functional, and market-ready products efficiently:

- Expert Fabric Selection: Provides guidance on the optimal material blends for comfort, stretch, moisture-wicking, durability, and support, ensuring fabrics suit the intended activity level. This expertise is equally critical for a t-shirt manufacturer focused on performance wear

- Design & Functional Advice: Offers recommendations on construction details, support features, and design tweaks to enhance both performance and wearer comfort.

- Optimized Fit & Sizing: Develops precise patterns and grading for different body types, ensuring consistent fit, support, and comfort across all sizes. This is a core strength of any proficient cut and sew manufacturer.

- Efficient Production Methods: Applies advanced sewing techniques and workflow optimizations that maintain quality, minimize errors, and improve production speed.

- Quality Consistency: Guarantees that each unit matches the approved sample, ensuring uniformity in stitching, elasticity, and overall performance across batches.

- Problem-Solving Experience: Anticipates and resolves common manufacturing challenges such as seam stress, fabric distortion, or elasticity loss, reducing defects and returns.

- Faster Time-to-Market: Streamlined processes and expertise shorten development cycles, enabling brands to launch collections more quickly.

- Compliance & Certifications: Ensures production aligns with industry standards for safety, labor practices, and sustainability, providing credibility and peace of mind for brands and consumers.

5. Typical Lead Times for Sports Bra Production

In apparel production, lead time is a critical factor for a successful product launch. Knowing the duration of each stage from fabric sourcing and sampling to bulk production, quality checks, and shipping helps brands plan internal operations like marketing and sales.

Accurate timelines prevent last-minute stress, production bottlenecks, and supply chain issues. By managing lead time effectively, brands can respond confidently to market trends and deliver products on schedule.

Production timelines depend on several variables, from design complexity and material sourcing to sampling rounds and production capacity. For a bulk order of thousands pieces, the typical timeline includes:

- Inquiry & Quotation: 3-5 days to review the tech pack, assess materials, and prepare a custom quotation.

- Sample Development: 2-3 rounds of sampling, each taking 7-10 days using in-stock fabrics. Sampling fees are usually charged upfront and refunded upon bulk order confirmation.

- Bulk Production: Standard production generally takes 30-45 days once all fabrics and trims are available.

- Quality Control & Packaging: 100% end-line check; AQL standards enforced. Third-party inspection possible. Issues must be resolved before proceeding.

- Packaging & Delivery: Products shipped by air or sea. The timeline depends on the destination.

- Expanding Your Collection: Many brands that start with sports bras successfully expand into complementary categories. The technical understanding of fit and fabric gained from sports bra production is highly transferable. Partnering with a manufacturer that also has experience as a hoodie manufacturer or works with streetwear apparel manufacturers can provide a seamless path to creating coordinated athleisure sets and full collections, leveraging the same supply chain for efficiency.

FAQs

How long does it take to produce a sports bra sample and bulk orders?

Our standard lead time for bulk production is typically 30-45 days after receiving all fabric and trims. Sampling takes 7-10 days if using available fabric.

Which industry certifications has the Thygesen obtained?

We hold ISO 9001:2015 for quality management; SA8000, WRAP, and Better Work for ethical and sustainable manufacturing; and GRS, GOTS, OCS, FSC, OEKO-TEX® STeP, and Oeko-Tex® Standard 100 for certified materials and products.We suggest eco-friendly fabrics such as recycled nylon, recycled polyester, organic cotton, bamboo, Tencel™, and modal for producing seamless leggings, all sourced from our trusted suppliers to ensure high quality.

What testing procedures has Thygesen implemented in sports bra manufacturing before delivering the final products to clients?

We conduct rigorous testing, including material testing, 100% in-line inspections, and final AQL (Acceptance Quality Limit) checks to ensure quality and compliance.Every product undergoes 100% end-line inspections to ensure quality, checking texture, stitching, seams, stretchability, and measurements. We apply the AQL standard for consistency, approving only those that pass.

Our Clients Say

Start Your Production with Thygesen Vietnam