Vietnam is a top destination for many famous fashion brands seeking apparel production, thanks to its skilled workforce and competitive pricing. Discover top best clothing manufacturers in Vietnam, known for their expertise, strong production capabilities, and ethical values.

1. Top 10 Best Clothing Manufacturers in Vietnam

Here’s a list of the 15 best clothing manufacturers in Vietnam to consider when working on your clothing brand. These manufacturers are known for their quality and reliable production.

1.1. Thygesen Textile Vietnam – A Reliable Clothing Manufacturer in Asia

Thygesen is one of the best clothing manufacturers in Vietnam with two factories in the north of Vietnam and a headquarters in the capital, Hanoi, offering full-package clothing manufacturing services that cover every stage of the production process, from fabric sourcing and technical design consultation to manufacturing, packaging, and final delivery.

- Name: Thygesen Textile Vietnam

- Founded: 1931

- Area of expertise: Garment manufacturing

- Product Lines: Activewear, Casualwear, Underwear, Kidswear, Uniform and Workwear

- Website: https://thygesenapparel.com/

- Contact info: [email protected]

As one of the top garment manufacturers in Vietnam, with over 90 years of experience in the textile industry and collaboration with various fashion brands such as: Calvin Klein, Tommy Hilfiger, Fjällräven, Girlfriend Collective, Thygesen provides expert advice on customizations from fabric selection, design, color to sizing, prints, embroidery, and labels or tags to deliver the best results, perfectly aligned with customer needs.

Especially for activewear and underwear lines, Thygesen utilizes Santoni seamless technology to manufacture products like leggings, sports bras, panties, and boxers, with features like moisture-wicking, antibacterial properties, and UV protection to enhance performance and comfort.

Notably, sustainability and ethical practices are core to Thygesen’s values. Thygesen is committed to responsible manufacturing and workers’ rights, demonstrated through certifications like SA8000 & WRAP, ISO 9001:2015, and OEKO-TEX® Standard 100.

>> If you’re looking to start your own clothing brand or create unique merchandise, choosing the right hoodie manufacturer is essential for quality and success. Explore detail through this article!

1.2. Thanh Cong Textile and Garment JSC

Thanh Cong Textile specializes in a closed production process from yarn to knitting/weaving, dyeing, and sewing, Thanh Cong is well-known for its high-quality products, including T-shirts, polo shirts, sportswear, children’s wear, outerwear, uniforms, and underwear.

- Name: Thanh Cong Textile

- Founded: 1964

- Area of expertise: Sewing, Dyeing, Knitting, Weaving, Spinning

- Website: https://www.thanhcong.com.vn/

- Contact info: [email protected]

With raw materials such as 100% cotton, TC, and CC, and advanced machinery imported from Japan, Korea, China, and Taiwan, Thanh Cong has built a strong reputation among both domestic and international customers.

1.3. Hanosimex

Hanosimex specializes in manufacturing and trading knitted clothing, fiber, and knitted fabrics. Additionally, the company supplies materials and accessories to other businesses within the textile industry, playing a key role in the textile supply chain.

- Name: Hanoi Textile and Garment

- Founded: 1984

- Area of expertise: Yarn and Sewing

- Website: http://www.hanosimex.com.vn/

- Contact info: [email protected]

Currently, Hanosimex operates 4 factories with nearly 4,500 staff members and workers, enabling it to efficiently manage large-scale production and meet the demands of its clients in the textile industry.

1.4. TAL

TAL produces high-quality men’s dress shirts, with a focus on non-iron dress shirts, casual woven shirts, and polo shirts.

- Name: TAL Apparel

- Founded: 1947

- Area of expertise: Garment Manufacturing

- Website: https://www.talapparel.com/

- Contact info: [email protected]

The TAL factory is known for its advanced manufacturing techniques and strong supply chain management, guaranteeing the production of durable, stylish, and innovative garments for the retail industry.

1.5. TCE Denim

TCE is a clothing manufacturer in Asia with two state-of-the-art factories based in Vietnam, specializing in sustainable denim production and laundry processes. The company manufactures and launders a range of denim products, including jeans, jackets, skirts, and denim shirts.

- Name: TCE Denim

- Founded: 1956

- Area of expertise: Denim Apparel Manufacturing

- Website: http://tcedenim.com

- Contact info: [email protected]

Their eco-friendly practices include water-saving dyeing methods, one-bath sulfur dyeing, aniline-free indigo dyeing, and the use of an eco-friendly sanforizing finishing machine, which reduces energy, water, and gas emissions.

1.6. VINATEX

Vinatex is one of the largest companies in Vietnam’s textile and garment sector, accounting for 97% of cotton seed production, over 33% of yarn production, nearly 32% of woven fabric output, and almost 13% of garment production. Additionally, it contributes to more than 18% of the total export turnover in the sector.

- Name: Vietnam National Textile and Garment Group

- Founded: 1995

- Area of expertise: Yarn, Fabric, Dyeing, Garment Manufacturing

- Website: https://vinatex.com.vn/

- Contact info: [email protected]

Vinatex produces 410 million garment units per year across a wide range of apparel types, including casual wear, sportswear, and technical textiles.

1.7. TNG

TNG operates 15 garment factories, producing over 55 million products annually, mainly jackets and kidswear and workwear.

- Name: Vietnam National Textile and Garment Group

- Founded: 1979

- Area of expertise: Garment Manufacturing

- Website: https://tng.vn/

- Contact info: [email protected]

TNG is known for its advanced technology and modern facilities, focusing on both domestic and international markets. Besides apparel sewing, the company provides services such as quilting, embroidery, printing, and industrial washing.

1.8. Fashion Garments

Fashion Garments (FGL) manufactures a wide range of apparel products, including jackets, shirts, trousers, activewear, and other types of casual and workwear.

- Name: Fashion Garments

- Founded: 1994

- Area of expertise: Apparel Manufacturing

- Website: https://www.fashiongarments.com/

- Contact info: [email protected]

FGL operates 4 advanced manufacturing factories in Dong Nai, Vietnam, employing over 10,000 staff. These vertically integrated factories offer a comprehensive range of capabilities, including their own weaving mill, washing plant, embroidery, and in-house printing.

1.9. Nha Be Garment (NBC)

Nha Be Garment is a Vietnam apparel manufacturer specializing in providing comprehensive solutions under ODM, FOB, LDP, DDP, and CMPT models.

- Name: Nhabe Garment Corporation

- Founded: 1992

- Area of expertise: Apparel Manufacturing

- Website: https://www.nhabe.com.vn/

- Contact info: [email protected]

With large-capacity factories, the company produces millions of products monthly, including knitwear, tailored suits, outerwear, activewear, sportswear, sweaters, dress pants, women’s fashion, uniforms, and workwear.

1.10. Thien Nam Prosperity (TNP)

Thien Nam Prosperity JSC (TNP Group) is a leading textile and garment partner for major global corporations.

- Name: Thien Nam Prosperity

- Founded: 2000

- Area of expertise: Yarn, Woven Fabric Weaving, Garment Manufacturing

- Website: https://tnp.vsscorporation.com/

- Contact info: [email protected]

With a fully integrated supply chain in Vietnam, TNP specializes in high-quality woven fabrics and garments, focusing on cotton, polyester blended yarns (TC, CVC), and products like shirts, dress pants, and suits.

1.11. Maxport

Maxport is an ideal option for brands seeking top garment manufacturers in Vietnam, especially for activewear production.

- Name: Maxport Limited Vietnam

- Founded: 1995

- Area of expertise: Active and Sportswear Manufacturing

- Website: https://maxportlimited.com

- Contact info: (+84) 0243 558 0941

The company is committed to upholding strong labor standards, ensuring top-quality products, fostering sustainability, and providing excellent working conditions for its workforce.

1.12. Hung Long

Hung Long is a garment manufacturer based in Vietnam, specializing in jackets for many global brands.

- Name: Hung Long

- Founded: 1996

- Area of expertise: Woven Clothing, Activewear, Jackets Manufacturing

- Website: http://mayhunglong.vn/

- Contact info: [email protected]

The company exports mainly to the USA, Europe, Japan, and South Korea and holds important ethical certifications such as WRAP, GSV, and Better Work, showcasing its dedication to ethical manufacturing practices and labor standards.

1.13. VIT Corporation

VIT Garment, located in Vietnam, focuses on producing high-quality apparel for international brands. The company is recognized for its dependable quality, utilizing state-of-the-art automated equipment and a fully integrated production line

- Name: VIT Corporation

- Founded: 1991

- Area of expertise: Denim Manufacturing

- Website: http://www.vitcorp.vn/

- Contact info: [email protected]

VIT Garment is committed to sustainability, investing in advanced wastewater treatment systems to safeguard the environment while upholding ethical manufacturing practices and maintaining high labor standards.

1.14. Phong Phu Corporation

Phong Phu Corporation is one of top manufacturers in Vietnam, offering a fully integrated supply chain from yarn production to weaving, dyeing, and garment manufacturing.

- Name: Phong Phu Corporation

- Founded: 1964

- Area of expertise: Yarn, Thread, Fabric, Garment Manufacturing

- Website: https://www.phongphucorp.com/

- Contact info: [email protected]

With advanced technologies like LEAN and automated systems, Phong Phu creates distinctive, high-quality garments that are trusted by both domestic and international customers.

1.15. Viet Thang Corporation

Viet Thang headquartered in Ho Chi Minh City, is a prominent textile and garment manufacturer in Vietnam.

- Name: Viet Thang Corporation

- Founded: 1964

- Area of expertise: Yarn, Fabric, Garment Manufacturing

- Website: https://vietthang.com.vn/

- Contact info: [email protected]

The company operates multiple specialized garment production lines, including shirts, blouses, uniforms, dress pants, shorts, cargo pants, wrinkle-free garments etc. With an annual capacity of 1.8 million shirts and 2.6 million trousers, the company exports to major markets like the USA, Germany, France, Japan, the UK, Canada, South Korea, and Sweden.

2. How to Find the Right Clothing Manufacturers in Vietnam?

Working with one of the top garment manufacturers in Vietnam can offer long-term benefits, ensuring that your brand aligns with core values like quality, sustainability, and reliable production. Finding the right clothing manufacturer requires a strategic approach to guarantee quality, reliability, and alignment with your business needs. Follow the steps below to achieve the best results.

- Step 1. Identify Needs: Start by defining your specific requirements, including product types, materials, and production volume. Research market trends, potential risks, and opportunities, so you can make informed decisions when choosing a manufacturer.

- Step 2. Searching: Look for potential manufacturers using online tools, social media, and trade shows. Gather recommendations and evaluate their commitment to sustainability, certifications, and quality standards. Compare different manufacturers to create a strong shortlist.

- Step 3. Contact and Shortlist: Reach out to potential manufacturers through emails, calls, or meetings. Requesting detailed company profiles and certifications or visiting their factories and sharing your specific needs will help refine your shortlist.

- Step 4. Receive Quotation/Proposal/Offer: Ask for detailed quotations or proposals. Engage in discussions to clarify pricing, terms, and production details, including any potential additional costs. Compare offers from multiple manufacturers to make sure you’re getting the best deal.

- Step 5. Sample Making: Request a prototype or sample to evaluate the manufacturer’s craftsmanship. You can either pay for a custom sample (typically around 50-100 USD) or review an existing one from the manufacturer. Provide feedback for improvements, and assess samples from different manufacturers to determine the best fit for your needs.

- Step 6. Negotiate, Contract, and Place Order: Discuss key details like payment terms, production timelines, quality control, and risk-sharing. After finalizing the terms, place your order.

- Step 7. Production and Quality Control: Monitor production closely through regular updates and reports. Verify that quality control is maintained, either internally or with third-party inspectors. Address any issues promptly to guarantee product quality and timely delivery.

3. Tips for Working with Top Garment Manufacturers in Vietnam

When working with the best clothing manufacturers in Vietnam, there are many key factors to consider for a successful partnership. Below are essential tips to help you build an effective and productive partnership with the best Vietnam clothing manufacturers:

- Request Detailed Profiles: Ask clothing manufacturers to provide a detailed product catalog, certifications, and capability profiles. This helps avoid making incorrect judgments about new partners, saving time and resources, and preventing the overlooking of potential, suitable partners.

- Understand the Services They Provide: Inquire about the specific services offered by the manufacturer, such as customization options for design, material choices, sizing, labeling, packaging and logistics. Understanding these services will help you determine how flexible the manufacturer is in meeting your unique product requirements.

- Evaluate Capacity and Craftsmanship: Assess the manufacturer’s production capacity and craftsmanship by reviewing their facilities, certifications, and the quality of sample products. A factory visit can help verify whether the supplier can meet your production needs and deliver products that align with your quality standards.

- Request Cost Transparency: Request detailed quotes for each item, compare prices among garment manufacturers, and review any potential additional costs. Avoid clothing manufacturers who provide unclear or overly general quotes. For sourcing agencies, avoid apparel manufacturers trying to bypass agreements by directly engaging with customers.

- Check Product Quality: Carefully check the quality of mass-produced items to make sure the final products meet the agreed-upon standards and match the approved sample.

- Communicate Clearly on Production Progress: Request regular updates on production progress and a clear procedure for addressing any challenges. Make sure that if the manufacturer collaborates with third parties for products beyond your company’s capabilities, or for tasks like printing or embroidery, you are informed about their involvement.

- Confirm Manufacturers’ Responsibility: Confirm that the supplier takes responsibility for their commitments regarding delivery times and product quality. If there are any delays or the final products do not meet the agreed specifications, the supplier should be held accountable, including addressing any faulty products, even if third-party inspections have been done.

- Prioritize Ethical Practices: Avoid apparel manufacturers who engage in unethical practices, such as leaking products, violating NDA (Non-Disclosure Agreement), disclosing business secrets to competitors, or using unethical labor or materials

- Supportive Service: Make sure the supplier is responsive to feedback, willing to make improvements, and capable of offering solutions when challenges arise and proficient in a language you can comfortably communicate in. Effective communication is essential to avoid misunderstandings and to ensure the final product meets your expectations.

4. FAQs

4.1. Why has Vietnam become a popular choice for brands seeking apparel manufacturing services?

Vietnam has become a popular choice for brands seeking apparel manufacturing services due to several key advantages. Key factors include:

- Political Stability: Vietnam offers a stable political environment, making it an attractive destination for foreign businesses to invest in and establish production operations.

- Trade Agreement Benefits: Vietnam has signed numerous free trade agreements like UKFTA, EVFTA with various countries and regions. These agreements reduce or eliminate import-export duties, enhance market access, and simplify trade procedures.

- Competitive Pricing: The cost of manufacturing in Vietnam is more affordable compared to producing locally in countries like the US, Australia, or Europe. This includes lower labor, material, and transportation costs, along with attractive tax incentives.

- Quality and Standards: Vietnam is well-known for producing high-quality apparel, with exceptional craftsmanship. Many customers expect products made in Vietnam to meet or exceed international quality and social responsibility standards, such as ISO 9001, WRAP, SA8000, GOTS, etc.

- Flexibility and Customization: Manufacturers in Vietnam are known for their ability to meet customization requirements, offering flexibility in terms of design, patterns, and production volumes.

- Skilled Labor: Vietnamese workers are well-trained and skilled, particularly in garment making and finishing, which contributes to high product quality and reduced defects.

- Supply Chain Assurance: The best Vietnam clothing manufacturers are well-connected with reliable domestic suppliers, enabling a stable supply chain for raw materials. Sourcing locally also provides the advantage of reduced import tariffs offering significant cost savings.

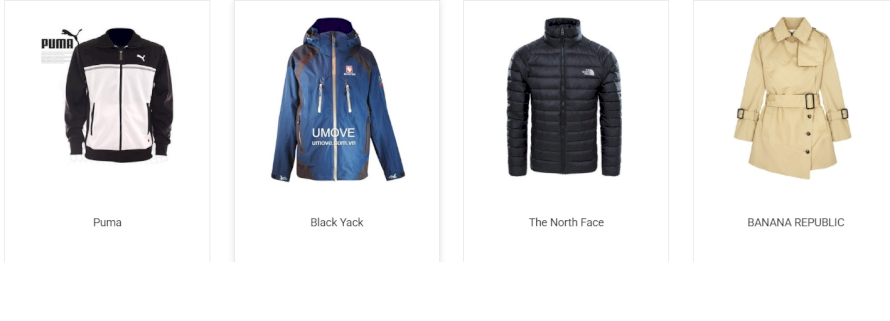

- Brand Reputation: Many customers believe that products labeled “Made in Vietnam” enhance their brand reputation, as the label is widely regarded as a mark of quality and credibility in the marketplace, often preferred over “Made in China”. Many well-known brands, including Nike, Adidas, Uniqlo, Puma, etc. produce clothing in Vietnam to take advantage of the country’s strong manufacturing capabilities.

4.2. What is the average lead time of the best clothing manufacturers in Vietnam?

The lead time for clothing manufacturers in Vietnam depends on factors such as order size, material availability, and factory capabilities. For a typical order:

- Sample Development: Generally takes 7-10 days, depending on the complexity of the design.

- Production for 3,000 Units: Including material sourcing or development, the lead time is typically 10–12 weeks.

4.3. Which famous brands have worked with clothing manufacturers in Vietnam?

Many famous brands such as Nike, Adidas, Uniqlo, H&M, Zara, The North Face, Patagonia, Puma, Gap, Levi’s, Lululemon, Girlfriend Collective, Boody etc. have worked with clothing manufacturers in Vietnam due to the country’s skilled workforce, cost efficiency, and strong textile manufacturing infrastructure.

4.4. What are the shipping options available from Vietnam to international markets?

When shipping products from Vietnam to international markets, businesses typically choose between air freight and sea freight, with shipping terms like FOB (Free on Board) and DPP (Delivered Duty Paid) depending on their needs and agreements. Below are the options:

- Air Freight: Offers faster delivery times, ideal for urgent or smaller shipments, but comes at a higher cost compared to sea freight.

- Sea Freight: A more economical option for large volumes, though it requires longer transit times.

- FOB (Free on Board): The seller handles costs and responsibilities up to loading the goods onto the vessel at the port of shipment. From there, the buyer assumes control, including freight, insurance, and import duties.

- DPP (Delivered Duty Paid): The seller manages the entire shipping process, including transport, insurance, and import duties, delivering the goods to the buyer’s specified location. This option is often preferred for its convenience, as it minimizes the buyer’s involvement in logistics.

In conclusion, Vietnam stands out as a leading destination for apparel manufacturing, offering skilled craftsmanship and competitive pricing. Above is all the information about the list of top Vietnam apparel manufacturers. It’s important to note that partnering with the right manufacturer can enhance your brand by delivering high-quality products that align with your business goals.

Thygesen Textile Vietnam is one of the best clothing manufacturers in Vietnam, ready to support your brand with exceptional products and services. To inquire about our manufacturing services, please feel free to reach out at [email protected].