Thygesen Textile Vietnam – A Devoted Seamless Leggings Manufacturer

Custom Seam Leggings

Made From High-Quality Materials

We offer a wide selection of high-quality fabrics, including both available and fully customizable options. Our suppliers can develop custom fabrics with features such as stretchability, UV resistance, odor control, and enhanced durability. Additionally, we offer a wide range of certified fabrics such as GOTS organic cotton, OEKO-TEX® Standard 100, recycled polyester (GRS-certified), and bamboo fabric

To ensure the best materials, we source fabrics both locally in Vietnam and globally from leading textile markets such as Taiwan, Korea, Japan, India, and China. Our strong partnerships with trusted suppliers allow us to maintain high standards and deliver fabrics that meet customers requirements.

Crafted with

Cutiing Edge Machinery

Our seamless leggings are produced using Santoni seamless knitting machines, ensuring a smooth, stitch-free finish for maximum comfort and flexibility. Instead of traditional cutting methods, we use laser cutting technology to achieve sharp, precise edges while preventing fraying.

For certain design elements, we also apply heat-pressing techniques to enhance durability and aesthetics. By utilizing high technology, we deliver premium seamless leggings that meet the highest standards of quality.

Optimized for Efficiency

Our LEAN Process Minimizes Waste

By carefully planning material usage, we reduce fabric waste while ensuring each piece is efficiently produced. Our streamlined workflow minimizes unnecessary steps, improving productivity and consistency.

We also focus on efficient resource allocation, from fabric utilization to labor management, to enhance sustainability and cost-effectiveness. With our LEAN approach, we deliver high-quality seamless leggings while reducing environmental impact and maximizing value for our clients.

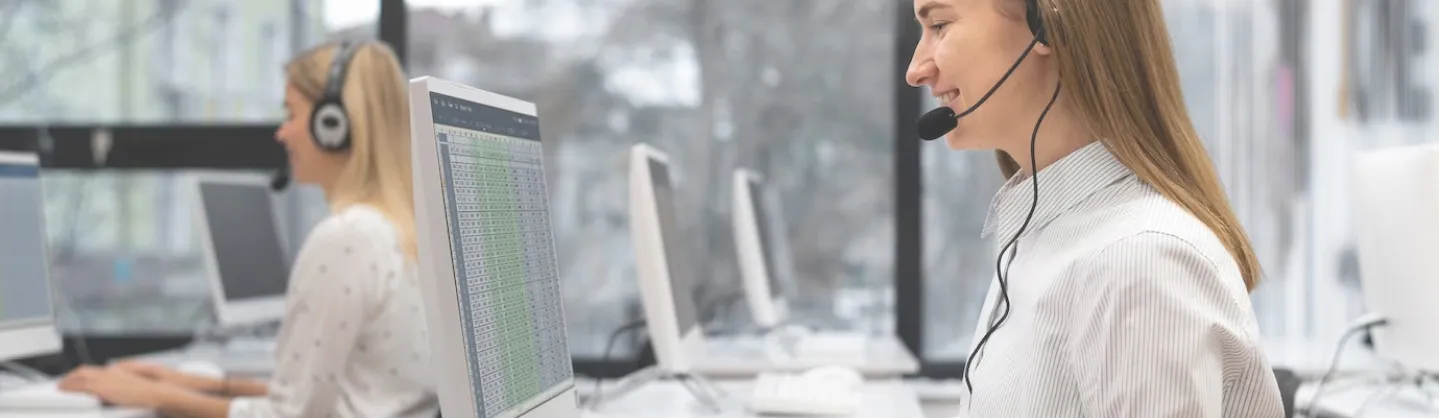

Driven by Professionalism

Customer Satisfaction Is Our Priority

At Thygesen Textile Vietnam, we ensure seamless collaboration through clear, efficient communication. Using digital tools, we manage projects remotely while maintaining timelines and swiftly resolving issues. We take a responsible and professional approach to handling arising matters, ensuring transparency in processes, contracts, and commitments.

Our dedication to professionalism and open communication builds strong, long-term partnerships and drives customer satisfaction at every stage of production.

We Bring All Your Compression Clothing Designs To Life

with Passion and Care

Showing

1-1

of

32

results

How Are Our OEM/ODM Solutions Different?

| Thygesen (FOB) | Traditional Clothing Manufacturer (CM) | |

|---|---|---|

| Full Package Service (From fabric sourcing to production and shipping) | ||

| Technical Design Assistance | ||

| Custom Labels, Hang Tags, Packaging | ||

| Cost Effective For Large Orders | ||

| Quality Assurance | ||

| Compliance & Global Certifications | ||

| Wide Network of Trusted Suppliers Both Local and Global | ||

| English Proficiency |

Our Process Setup is Optimized for Mass Production

Step 1

Handle Customer’s Inquiry

Send us an inquiry and share more details about your projects, and our dedicated team will handle it.

Step 2

Make Quotation

If your project is suitable for our standard MOQ and production, then we offer an initial quotation based on the techpack, selected fabric quality, and quantity.

Step 3

Sample Development

After the customer’s approval of the quotation, we proceed with sample development to confirm quality before starting bulk production.

Step 4

Bulk Production

Following order confirmation and a deposit, we initiate bulk production with all specifications carefully followed.

Step 5

Quality Control

We follow strictly our QC procedures, ensuring 100% end-line inspections. We also apply AQL 2.5 for final inspections. Third-party QC is always welcome.

Step 6

Packaging & Shipping

Once the quality is confirmed, the finished products are carefully packaged and shipped in bulk to your warehouse.

Partner with Us for Your Seamless Leggings

Tell us about your ideas, and we will make your vision become reality.

Seamless Legging Manufacturers: Buyer's Guide for All Fashion Brands

Seamless leggings offer unmatched comfort and performance, but they require a different approach than regular activewear. This guide covers the key differences, costs, and factors you need to know for seamless leggings manufacturing.

1. Key Differences and Considerations Compared to Regular Legging Production

Producing seamless leggings involves distinct techniques and considerations compared to regular leggings, influencing everything from fabric selection to construction methods and overall performance.

1.1. Fabric Selection and Performance Requirements

When it comes to seamless leggings, fabric choice is even more critical than in regular production because the entire garment is knitted as one continuous piece. Fabrics typically used:

- Nylon-spandex: Soft, durable, quick-drying, and supportive – ideal for high-performance activewear.

- Polyester-spandex: Lightweight, colorfast, moisture-wicking, and more affordable for large-scale production.

- Recycled synthetics (recycled nylon or polyester): Eco-friendly alternatives that maintain strength, elasticity, and moisture control while reducing environmental impact.

- Polyamide blends: Known for their smooth texture, compression support, and resistance to pilling.

- Functional yarns (e.g., Coolmax®, Tactel®, or Dryarn®): Provide enhanced breathability, thermal regulation, and comfort during intense workouts.

These fabrics are engineered to deliver 4-way stretch, fast moisture evaporation, and long-term shape retention – all essential for performance and comfort during training. An experienced legging manufacturer will have the expertise to guide brands in selecting the right fabric blend to achieve the desired balance of compression, opacity, and durability.

In contrast, regular leggings often use cotton blends or heavier polyester, focusing more on softness and everyday comfort rather than athletic performance.

1.2. Stitching and Seam Construction

Regular leggings are made by cutting and sewing multiple fabric panels together, resulting in numerous seams running down the legs and hips. While these seams help shape the garment, they are the most likely points of failure (where threads pop) and the main cause of chafing, reducing comfort during intense activity.

Seamless leggings are knitted as a continuous tube, which allows them to eliminate most seams (especially the outer and inner leg seams). They only require a few minimal and strategic seams, primarily at the crotch (to insert the gusset) and to finish the waistband. This construction makes seamless leggings extremely comfortable, more durable due to fewer weak points, and results in a smooth, irritation-free surface against the skin.

>>> For brands requiring precision and performance in their activewear lines, Thygesen offers extensive experience in advanced seamless knitting technology. Thygesen supports partners from initial design to final production, ensuring functional and high-quality garments. Consider Thygesen among your potential athletic apparel manufacturers to elevate your product offerings and meet rigorous market demands.

1.3. Dyeing and Printing

There are several main ways to add color and patterns to fabric: Yarn Dyeing (coloring the yarn before knitting), Piece Dyeing (coloring a whole roll of flat fabric), Garment Dyeing (coloring the finished piece), and Printing (applying color on top of the fabric). Knitting machines also allow for patterns to be created by Jacquard knitting (Knit-in Patterning) using different colored yarns.

Regular leggings typically use piece dyeing for solid colors or printing on the flat fabric roll to create large, complex designs, prioritizing design freedom. In contrast, seamless leggings mainly use yarn dyeing or garment dyeing if they need a simple solid color. Seamless leggings mainly use yarn dyeing or garment dyeing if they need a simple solid color. They rely on Jacquard knitting if they need multi-colored patterns, complex textures, or functional compression zones built directly into the garment structure.

1.4. Cost & MOQ

- Cost: Seamless leggings generally have a higher upfront cost due to specialized circular knitting machines and advanced yarns. However, they help reduce fabric waste and sewing labor, which can offset part of the cost at scale. Regular leggings, on the other hand, are more affordable to start with, as they use conventional fabrics and simpler cut and sew manufacturing methods.

- Minimum Order Quantity (MOQ) and Flexibility: Regular leggings are suitable for low MOQs and offer high flexibility to change patterns between small batches. However, seamless leggings require a higher MOQ to offset the significant setup and programming costs, making them less flexible for small orders or frequent design changes.

2. Seamless vs. Seamfree Leggings – What’s the Difference?

“Seamless” and “seamfree” are often thought to be the same, but they are actually different production techniques.

2.1. Seamless Leggings

Seamless refers to the manufacturing method itself:

- How it’s Made: A legging labeled “Seamless” is knitted on a specialized circular knitting machine that produces the main body and leg tubes as a single, continuous piece, like a giant sock.

- Result: The garment is structurally engineered from the yarn up. This process minimizes seams entirely, eliminating the traditional outer-leg and side seams.

- Seam Reality: Even “seamless” garments still have a few necessary seams: the gusset/crotch seam (to join the two leg tubes and allow flexibility) and sometimes a seam to attach the waistband. The key is that the major seams causing friction are gone.

- Core Benefit: Superior comfort, flexibility, and the ability to knit performance zones (compression, ventilation) directly into the fabric.

>>> Brands looking for comprehensive manufacturing partners to realize their design visions across various apparel categories will find Thygesen’s capabilities extensive. Thygesen applies its commitment to precision and quality management to a wide array of garment types, extending beyond seamless leggings. Explore how Thygesen’s production methodologies consistently deliver excellence, whether you are collaborating on seamless designs or seeking experienced hoodie manufacturers for your next collection.

2.2. Seamfree Leggings

Seamfree is an aesthetic description of the final look and feel:

- Meaning: It literally means “free of seams” or “without visible seams.”

- Usage: It is often used to describe garments that are made from Freecut or Bonded fabrics. These fabrics are cut and joined using heat or adhesive instead of stitching (like ultrasonic welding).

- Example: A piece of underwear can be made from two pieces of fabric that are bonded together with heat, making the edges and joints lie completely flat and invisible, thus, they are seamfree even if they weren’t produced on a circular knitting machine.

3. Are Seamless Leggings More Expensive to Produce?

Yes, seamless leggings are generally more costly to produce than regular leggings. The higher costs stem from both specialized machinery and technical requirements:

- Advanced machinery (e.g., Santoni machines): Seamless production relies on high-precision circular knitting machines like Santoni, which can cost hundreds of thousands of dollars. These machines enable complex patterns, integrated shaping, and high stretch recovery but also require skilled operators and longer setup times.

- Specialized yarns: High-performance blends such as nylon-spandex, polyester-spandex, or recycled synthetics are needed to achieve 4-way stretch, durability, moisture management, and long-term shape retention.

- Higher setup and sampling costs: Programming patterns, compression zones, and shaping into the knitting machine takes time and technical expertise, increasing labor and sampling costs.

- Minimum order quantities (MOQs): Due to machine setup requirements, MOQs are typically higher, impacting cost per unit for small orders. This stands in contrast to some other garment types, where ladies’ pajama manufacturer might offer more flexibility with smaller runs for testing classic sleepwear designs in the market.

- Quality control and consistency: Additional checks ensure proper fit, elasticity, and performance across the garment, adding to production expenses.

Overall, while seamless leggings are generally more expensive to produce, they offer fashion brands benefits such as superior fit, enhanced comfort, and durability, helping differentiate collections and justify higher retail prices.

4. What Brands Should Look for When Selecting A Seamless Legging Manufacturer

Choosing the right seamless legging manufacturer is a crucial step for brands, as it directly affects product quality, performance, and the ability to meet both design and sustainability goals.

4.1. Advisory & Expertise

When selecting a seamless legging manufacturer, it’s essential to choose one with hands-on experience in seamless production. A knowledgeable partner can provide technical guidance on critical elements such as material selection for stretch, durability, and comfort, garment fit and sizing considerations, and compression zone placement for performance and support.

Since seamless leggings require a very different approach than traditional cut-and-sew garments, working with a manufacturer who understands these technical nuances ensures the final product is optimized for fit, performance, and overall wearer experience. The right partner will also be able to advise on other knit categories, potentially serving as a knowledgeable pajama manufacturer for seamless or technical loungewear lines.

4.2. Transparency

Clarity and openness are essential when partnering with a seamless legging manufacturer. It’s important to understand whether production is handled in-house or outsourced to a subcontractor, especially since seamless machinery is highly specialized and costly.

The manufacturer should also be transparent about their quality control processes, production standards, and minimum order quantities (MOQs), helping brands plan costs, lead times, and ensure consistent product quality.

4.3. Quality & Consistency

Consistency is crucial in seamless legging production, as even small variations can impact garment performance and how customers perceive your brand. Choose a manufacturer with robust systems to ensure reliable stretch performance, accurate color, precise stitching, and consistent finishing across every production run.

Maintaining this high level of quality control is essential for protecting brand reputation and delivering a premium product that meets consumer expectations.

4.4. Sustainability & Ethical Practices

Choose a partner that follows fair labor practices and environmentally responsible processes. Since seamless production often involves specialized equipment and higher resource use, it’s important that the manufacturer operates sustainably – from sourcing eco-friendly yarns to minimizing waste and adhering to ethical standards. Certifications such as GRS, OEKO-TEX®, WRAP, and SA8000 demonstrate a commitment to quality, social accountability, and environmental responsibility.

Working with a certified, sustainable manufacturer not only enhances brand credibility but also helps meet growing consumer expectations. This commitment to eco-friendly production is equally valuable for a custom bamboo pajama manufacturer, where the use of sustainable materials is a key selling point for brands.

FAQs

What is your MOQ for seamless leggings manufacturing at Thygesen?

The pricing of leggings manufacturing at Thygesen is influenced by fabric choices, design complexity, customization, production volume, and manufacturing processes. High-performance fabrics and additional features like custom prints or stitching can increase costs, while larger production volumes generally lower the price per unit.

Which eco-friendly fabrics does Thygesen recommend to produce seamless leggings?

We suggest eco-friendly fabrics such as recycled nylon, recycled polyester, organic cotton, bamboo, Tencel™, and modal for producing seamless leggings, all sourced from our trusted suppliers to ensure high quality.

Which quality certifications that Thygesen holds?

We hold quality certifications such as GSV and ISO 9001:2015, ensuring compliance with international standards for safety, quality management, and ethical production.

What quality control processes does Thygesen Textile Vietnam apply?

Every product undergoes 100% end-line inspections to ensure quality, checking texture, stitching, seams, stretchability, and measurements. We apply the AQL standard for consistency, approving only those that pass.