Paragon Fitness is a performance-focused activewear brand known for its clean aesthetics, functional designs, and community-driven approach to fitness apparel. To deliver consistent quality, comfort, and durability, Paragon carefully works with manufacturing partners that align with its standards for craftsmanship and responsible production. Below, we’ll explore where Paragon Fitness clothing is made.

1. About Paragon Fitness and Its Product Lines

Paragon Fitness is a women’s activewear brand founded in the USA in 2013 and headquartered in Ada, Michigan. The company was started with the mission to create high-quality, performance-driven activewear that supports strength training and everyday fitness goals.

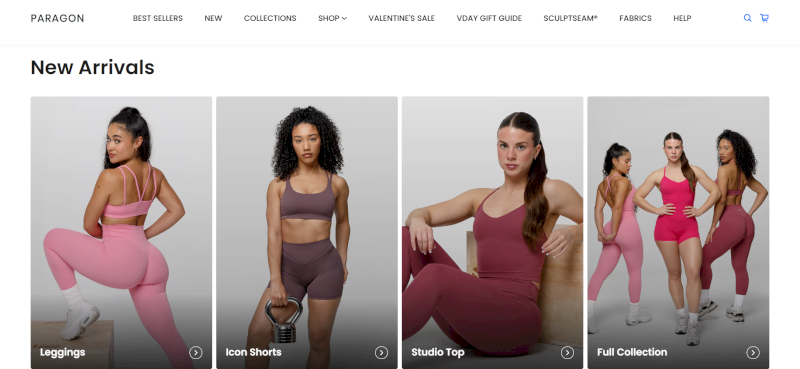

The brand designs gym and workout apparel including leggings, shorts, tops, and sports bras with a focus on fit, comfort, and flattering silhouettes. Paragon is known for innovations like its Sculptseam® hidden scrunch technology, introduced in 2020 to enhance glute contouring without visible seams.

Paragon positions itself toward fitness-minded women who want activewear that looks good and feels comfortable throughout workouts and daily wear. Products feature a variety of core fabrics for different activities, from low-impact to high-intensity workouts.

2. Where Is Paragon Fitness Clothing Made?

Paragon Fitness clothing is primarily manufactured in Asia, with production commonly associated with countries such as Vietnam and China, which are well-established hubs for activewear and performance apparel manufacturing.

2.1. China

China has historically been one of the largest and most influential manufacturing bases for activewear. The country is well known for its large-scale production capacity, highly developed supply chains, and long-standing experience in performance apparel manufacturing.

Paragon Fitwear produces its activewear primarily in China, with user reports indicating that items are shipped directly from there. While designed, developed, and headquartered in the U.S, the production is outsourced to overseas factories. According to the brand, they only partner with factories that pass social compliance audits such as BSCI or SA8000 to ensure fair labor practices.

2.2. Vietnam

Vietnam’s apparel industry has grown significantly over the past decade, especially in activewear and athleisure categories. These advantages below help explain why brands like Paragon Fitness choose Vietnam as a key manufacturing location for their activewear, ensuring consistent quality, reliable production, and responsible sourcing.

- Political Stability and Reliability: Vietnam’s stable political and social environment helps minimize production risks and supply chain disruptions, allowing global brands to plan long-term manufacturing and meet tight seasonal timelines with confidence.

- Strong and Specialized Supply Chain: Located at the heart of Asia’s textile manufacturing hub, Vietnam benefits from close access to major raw material and fabric sources across the region. The country has built a mature ecosystem for performance and activewear, with advanced mills producing technical fabrics, recycled synthetics, and moisture-management materials, helping brands shorten lead times and streamline logistics.

- Skilled Workforce with Competitive Costs: The country offers a highly trained workforce experienced in technical garment construction, paired with competitive production costs, delivering strong value for high-quality activewear manufacturing.

- Trade Agreements and Cost Advantages: With major FTAs such as EVFTA and CPTPP, garments made in Vietnam benefit from reduced or zero import duties in key markets, helping brands optimize costs and margins.

- Ethical and Sustainable Manufacturing: Many Vietnamese factories meet international standards like WRAP and Better Work, supporting transparent, responsible, and ESG-aligned production for modern activewear brands.

4. Thygesen Textile Vietnam – Activewear Manufacturing Partner

With over 90 years of experience in the textile industry, Thygesen Textile Vietnam has worked with Paragon Fitness as a manufacturing partner in Vietnam, contributing to the production of performance-focused activewear through strong craftsmanship and quality control and ethical manufacturing.

All garments are produced in facilities certified to SA8000 and WRAP, ensuring responsible labor standards and safe working conditions, alongside additional certifications including ISO 9001:2015, GRS, GOTS, OEKO-TEX® STANDARD 100, FSC, and OCS.

Beyond Paragon Fitness, Thygesen has partnered with international activewear brands such as Girlfriend Collective, Boody, Wilson, and Rockwear, building strong expertise in meeting diverse quality, performance, and compliance requirements across global markets.

We manufacture a broad range of activewear products, including leggings, sports bras, bike shorts, tank tops, T-shirts, hoodies, sweatshirts, joggers, base layers, performance tops, and seamless garments for both fitness and lifestyle use. With deep technical know-how, experienced teams, and in-house development capabilities, activewear remains one of Thygesen’s core strengths, enabling us to support brands from fabric selection and sampling through to scalable, high-quality production.

In conclusion, Paragon Fitness is a well-known brand recognized for its high-quality, performance-focused activewear. Thygesen Textile Vietnam has proudly partnered with Paragon to support their manufacturing in Vietnam. Contact us to learn more about our ethical and high-quality apparel manufacturing services by emailing sale@thygesen.com.vn or visiting our website: thygesenapparel.com.